- ·

The coefficient is for an

inappropriate temperature range for glass.

- ·

The

critical temperatures for expansion are in the annealing range, for which there

are no widely published figures.

- ·

The

expansion rates need to be adjusted to match the viscosity in this annealing

range.

- ·

A

major manufacturer has indicated their glass, known by the CoE of its fusing

standard glass, has a 10-point range of CoEs within their fusing range.

Sunday, 27 August 2023

Coe and compatibility

Compatibility of Glasses with the Same CoE

CoE Useage

The temperature range used is 20C to 300C. Expansion characteristics vary greatly at higher temperatures.

Whether you call it CoE or CoLE is immaterial, as it still does not equal compatibility.

It does measure expansion rates, but up to 300C only. It does not tell you how glass expands above that temperature. Note: it does not behave in a linear pattern as crystalline materials do.

"CoE Equals Compatibility" - Kiln Forming Myths 10

Other posts on Compatibility are here:

Is Coe Important?

What is Viscosity?

CoE varies with temperature

Defining the glass transition stage

Mixing COE

So, if you mix manufacturers' glass even though advertised as the same COE, it does not make them compatible. There is much more than expansion rates that goes into compatibility. You need to test different manufacturers' glass against each other before you use it.

These are notes on aspects of compatibility.

Is CoE Important?

|

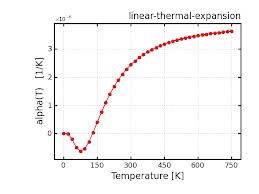

| Graph showing the change in the CoLE of aluminium between 0ºC and 527ºC (Kelvin being about 273 degrees lower than Celsius) |

|

| This graph shows a material that actually contracts briefly as it warms. Its CoLE would be between 20 and 35 - an extremely low rate of expansion. |

|

| This shows an idealised material that has a CoLE of about 40 at 0ºC and around 60 at 300ºC, remaining thereabouts as the temperature rises toward 1200ºC |

Wednesday, 23 August 2023

Is Pate de Verre Watertight?

Clear frit sintered at 690C, 670C, and 650C (left to right)

"This is fascinating. I

had no idea about the water leaving the glass at different temperatures."

Wednesday, 16 August 2023

The Mechanism of Sintering

"Do glass molecules actually migrate when they are sintered together? "

Sintering occurs at the atomic level,

where the atoms at the edge of the particles attach to others in other

particles. An analogy occurs to me of Scottish country dancing. In big

gatherings, small groups are formed to perform the dance, say an eightsome

reel. As the dance goes on the groups become more coordinated and eventually

form one large group, held together by the people on the edges of each group.

A more scientific description comes from

Wikipedia:

“Sintering … is the

process of compacting and forming a solid mass of material by heat or pressure

without melting it. … The atoms in the materials diffuse across the boundaries

of the particles, fusing the particles together and creating one solid piece.

Because the sintering temperature does not have to reach the melting point of

the material, sintering is often chosen as the shaping process for materials

with extremely high melting points such as tungsten and molybdenum.”

Applied to glass this means that you can make a solid piece of glass out

of multiple touching or overlapping pieces that do not change their shape. This

uses low temperatures and very long soaks.

|

| Schematic-diagram-for-the-sintering-and-fusion-reaction-of-the-glass-frits-on-a-substrate. Credit: ResearchGate |

The usual process is to take the glass at a moderate rate up to the

lower strain point. The rate of advance is slowed to 50°C or less to a

temperature between slumping and the bottom of the tack fuse range.

The slow rate of advance allows a lot of heat work to be put into the

glass. This, combined with a long soak (hours), gives the atoms of the molecules

time to combine with their neighbours in other particles.

Sintering occurs in the range of 610°C to 700°C (1130°F to 1275°F). The

lower limit is determined by the strain point of the glass and by practicality.

The length of time required at the strain point - 540°C/1005°F - is so long

(days) that it is impractical.

The upper limit is determined by the onset of devitrification. This has

been determined by the scientific studies of sintered glass as a structure for

growing bone transplants. Devitrification reduces the strength of the bonds of the particles at the molecular

level. The process of crystallisation breaks the bonds already formed between

the atomic structures of the molecules. These studies showed that the onset of

devitrification is at 650°C/1204°F and is visibly apparent at 700°C/1292°F

regardless of the glass used.

The lowest practical temperature for sintering is 650°C/1203°F. Indications

are that at least an additional two hours are needed for the sinter soak for

each 10°C/18°F reduction below 650°C/1203°F. This would make for a 12-hour soak

at 610°C/1131°F. For me this is not practical.

More information on

the kilnforming processes and sintering experimentation is available in this eBook: Low Temperature Kiln

Forming.

Wednesday, 9 August 2023

Fixing a Broken Piece

This conversation is reproduced by permission (with some editing out of extraneous information). It is presented as an example of how conducting a critique of your schedule can have dramatic effects on the results of your firing.

|

This is the piece as it came out of the kiln.

Picture credit: Ike Garson |

You may have seen the photo I posted of a large copper blue streaky piece that has cracked right across. … I’m wondering if it would be better trying to bring the 2 pieces together instead of opening up the 2 pieces and inserting frit. I was thinking of firing it with a tack or contour schedule.

|

This is the crack that developed later through the frit and single layer centre.

Picture credit: Ike Garson |

I have 4 questions:

A. Even

if I manage to fix it, do you think that fissure line will always be too weak

and liable to break off at any point?

The

strength of the joint will be dependent on the firing conditions. To make it strong, the temperature should go

to full fuse. Tack fusing will leave the

joint more visible and weaker. To stop

the joint rounding during heat up, you will need to dam the piece tightly to

stop the normal expansion of the glass and ensure the glass is forced together

during the higher temperatures.

B. I

have some large pieces of clear confetti. Would it benefit using them to bridge

the 2 sections from below?

Anything

you put on the bottom will have distinct outlines and visibility. The temperature on the bottom can be 10C or

more different from the top surface, which is why you can get crisp lines with

the flip and fire technique.

C. Would

clear powder hide the crack or would it always be visible after firing?

Any additions to the top may be less visible, but adding clear powder makes the join more obvious. You need to use powder of the same colour as the sheet glass. Since you are using a streaky glass, you can’t use coloured power either as it is very difficult to imitate the steaks even with powders of the same colours.

More

information was given indicating the first contour fuse schedule in Celsius:

- 260 730 00.20

- FULL 515 00.60

- 260 150 End

This is the contour schedule I have used many times

successfully but never for a piece during this week.

My critique of the schedule.

Segment

1.

- · It is too fast for the small distance to the side of the kiln.

- · It is too fast for a piece of varying thicknesses. Most expansion breaks occur above 300˚C, so a soak at ca.260˚C will help ensure the glass maintains an even temperature, especially with large differences in thickness. Then you can advance more quickly.

- · There is no bubble squeeze.

- · The top temperature seems low for a good tack, or the soak is a bit short. Long soaks allow the glass molecules to bind at the atomic level firmly. This is the principle used in pate de verre.

- · It definitely needs to be on fibre paper covered with thinfire to allow air out.

Segment

2.

- · The soak at 515˚C is better done at 482˚C for Bullseye.

- · My tests have shown that contour firing a piece like this at rates and holds for 1.5 times the height of the piece is necessary for good results.

Segment

3.

- · Also, my tests have shown that a three-stage cooling provides the best result. Slow cooling keeps the glass within the 5°C difference required for avoiding stress.

- · Annealing at the bottom end of the range combined with an appropriate length of soak and slow cooling gives a denser glass than soaking at the middle of the annealing range.

- · The best cooling comes from a three-stage cooling process. This involves a slow rate for the first 55C, a rate of 1.8 times this for the second 55C, and a rate of 3 times this for the final cool to room temperature.

These

points mean that I would recommend you fire for at least 10mm thick. This recommendation is for a new piece, not a

repair. In this repair case and for the conditions, I would choose 12mm as being

more cautious. My schedule would look something like:

- 120˚C to 260˚C, 20’

- 300˚C to top temperature, 10’

- Full to 482˚C, 120’

- 20˚C to 427˚C,0’

- 36˚C to 370˚C, 0’

- 120˚C to room temperature, off

The anneal soak is for a piece 12mm thick. The cool rates are for 21mm thick. This is to compensate for the nearness of the glass to the edge of the kiln. It will help to ensure the glass does not have excess stress locked into the piece during the cooling.

D. Do you think this schedule would work [for a repair]? It's adapted from a standard tack schedule..

- 222 677 00.30

- 222 515 00.40

- FULL 482 01.30

- 63 371 ENDS

Critique of the schedule.

Segment

1.

- · Too fast given earlier difficulties.

- · Too low for good adhesion unless you use about 10 hours soak.

- · Even at sintering temperature (690°C) you would need 2 hours. But at sintering temperature you do not alter the surface

Segment

2.

- · Too slow a cool from top temperature and risks devitrification. Should be FULL.

- · You do not need the soak at 515˚C. It only delays the annealing process. It seems this idea of soaking at the upper portion of the annealing range was introduced by Spectrum over 2 decades ago.

- · Any advantage that might be achieved by the higher soak is cancelled by the FULL rate to the annealing soak.

- · Go straight to the anneal soak.

Segment

3.

- · You need a more controlled 3 stage cooling to get the best result.

My schedule

for repair would look something like this:

- 120˚C to 540˚C, 10’

- 300˚C to 780˚C, 10’

- Full to 482˚C, 210’

- 20˚C to 427˚C,0’

- 36˚C to 370˚C, 0’

- 120˚C to room temperature, off

I am making the assumption that

780˚C is full fuse in your kiln.

Anything less than full fuse will certainly show the crack.

A Look at Causes.

- · The piece is far enough away from the elements. It is not on the floor. These are not the causes.

- · It is very near the sides of the kiln. These are always cooler than the centre. There is always a risk of breaking in this case. Very slow rates are needed.

- · There is a 3.5 times difference in thickness within the piece. This also requires slow rates.

- · If the break were to have been on the heat up these elements of uneven heating, and rapid rates are a problem. But the break occurred after the cool down. So, the annealing soak and cool is a problem.

- · I have suggested some alterations to the schedules to address these things.

Fixing

for Yourself

- · Dam it tightly to avoid expansion within the glass as it heats. This holds the join together and causes the glass to gain a little height.

- · Place the piece on 1mm or thicker fibre paper topped with thinfire. This will help avoid a bubble forming in the clear.

- · I have suggested a schedule which is slower to ensure no further breaks. It is slow to the strain point and fast after that.

- · It needs to be a full fuse to fully join the two pieces and ensure it is sound.

- · The cool to annealing should be FULL. Eliminate the soak in the upper annealing range. The effects of the time spent there is nullified by the rapid rate to the main annealing soak.

- · Anneal as for 12mm, but with slower cool rates (for 21mm) to ensure there are no stresses built into the piece by the nearness of the glass to the edge of the kiln.

- · These methods and schedules will make it a strong whole. But the join will still show on the bottom.

- · After fixing, if you are still not satisfied, break it up for incorporation in other projects.

Finally,

and unfortunately, I do not think it can be satisfactorily repaired for a

client. The crack will show on the back.

You will know it is a repair, rather than a whole. And that will reflect on

your feeling about the piece, and possibly your reputation.

Conclusion

The commission was successfully re-made from scratch by the

artist using some of my suggestions on scheduling. This is the resulting piece.

|

| Picture credit: Ike Garson |

Careful analysis of the conditions around a break are

important to making a successful piece in the future. Many factors were

considered, but the focus became the schedule. Analysis of each step of the

schedule led to changes that resulted in a successful piece with the original

vision and new materials.