Tuesday, 14 October 2025

How do I Evaluate Some Suggestions about Annealing?

Wednesday, 25 June 2025

Annealing temperatures by colour

It has been suggested that there are different annealing temperatures for different colour groups. This is not so.

All the colours in a single fusing compatible range are annealed at the same temperature. It is true that there are variations in the viscosities of different colours, but these are designed by the makers to be minor. Also relevant is that annealing can occur over a range, making concern about different viscosities within a fusing compatible line of glass less important. The anneal soak gives time for all the glass to reach the same temperature differential of ∆T = 5°C, where the viscosity differences will be so small as to be insignificant.

There are precautions that should be observed when combining strongly contrasting colours or contrasting styles. In general, hot and dark colours are less viscous than light and cool colours at slumping and above temperatures. There are also contrasting viscosities between opalescent and transparent colours. A cautious approach to these differences in viscosities is to anneal them as for one layer thicker than that for the profile of the finished item.

The annealing temperature remains the same for all the glass in a fusing compatible line, regardless of colour or style. The length of the anneal soak and cool rates may be altered for these contrasts, but not the anneal temperature.

Monday, 30 December 2024

Annealing Strategies

This is a power point presentation I gave a few weeks ago to a group. It may be of interest to others. There is no commentary.

Wednesday, 5 July 2023

Coe and Annealing

If you have changed CoE (i.e., the manufacturer), then the annealing temperature is different. If you don't correct that, it's never going to work quite right.

I have several

problems with this statement.

CoE does not determine

the manufacturer. There are several manufacturers who claim to manufacture

fusing glass to the same CoE.

No manufacturer

makes to one CoE. All manufacturers have to vary the CoE of a particular glass

to balance its viscosity. The CoE is a dependent variable. It depends on what

the viscosity of the colour is. Spectrum at one point stated their System96

glass had a 10-point variation in CoE number. Oceanside will be no different. Bullseye

have stated a 5-point difference. Other manufacturers have not stated their variations.

No manufacturer can guarantee compatibility with another’s. This is because the ingredients to make a fusing range of glass varies from one manufacturer to another. These variations can make the glass incompatible. To determine if you can combine two glasses from different manufacturers you need to do the compatibility testing yourself. The CoE number does not determine the temperature characteristics of the glass either.

Annealing

Having got my disagreements with the statement out of the way, I can go on to looking at differing annealing temperatures. There is a difference between annealing point and annealing temperature.

Annealing Range

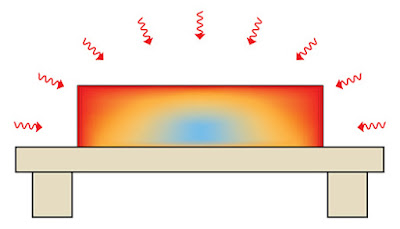

Annealing occurs over a relatively small range between the softening point at the higher end to the strain point at the lower end of the range. The softening point is the temperature, above which the glass is so plastic that it cannot be annealed. The strain point is the temperature at which the glass becomes so solid than no annealing can occur below it.

Annealing Point

The annealing point is mathematically determined as the

point at which the glass most quickly relieves the stresses within it. That temperature is determined by the viscosity of the glass. It is

known as the glass transition point, and is expressed as Tg. In practice there

are advantages in annealing at or below the published annealing point.

A soak above the annealing point is of no effect. Any

equalisation of temperature that occurs on that soak is negated by the drop to

the annealing point. It is better to spend the cumulative soak/hold time at the

(lower) annealing temperature.

Annealing Temperature

The average annealing point for Bullseye is 516°C/962°F. Different

formulations of their fusing compatible glass have different Tg temperatures. Research

showed the best results for their thick glass is 482°C/900°F. Other research in

academic institutions has shown that annealing at the lower part of the range

provides a denser and stronger finished glass piece. This applies to thick as

well as thin glass.

Bullseye has chosen to use a temperature 34°C/61°F below the

average annealing point, based on their research. This is still about 7°C/13°F

above the strain point. This approach can be applied to any fusing glass.

The strain point is approximately 43°C/78°F below the mathematically determined annealing point. If you know the annealing point you can choose to anneal – i.e., equalise the temperature of your glass – up to 30°C/54°F below that.

This has a practical demonstration. Wissmach for some

years designated 510°C/950°F as the annealing point for W96. A few years ago,

they changed their recommended annealing temperature to be 482°C/900°F. The annealing

results are good at both temperatures. The difference is that the annealing

soak is for a in longer time at the lower than at the higher temperature. But it still provides a shorter annealing cool.

Firing with different anneal points

This apparent diversion - into annealing ranges - shows that

it is possible to anneal glass with slightly different glass transition points

at the same temperature. You may compromise a little for one glass or the other.

You will also use longer times at the annealing temperature.

The annealing soak of Oceanside and Wissmach96 could both be

at 482°C/900°F. Or, if it felt safer, it can be an average of the two. The

average of the difference would make the annealing soak at 496°C/926°F. You

would use a longer soak at this temperature than at the higher one. The safest

would be to hold for an hour instead of 30 minutes for 6mm/0.25” of glass.

However, if the annealing point differs greatly, it is much

more difficult. For example, float glass with an annealing point of

540°C/1005°F would be difficult to fit in the same firing with most fusing

glass because of the wide range of official annealing points.

It is possible to anneal different glass at the same time if

the annealing points are not widely different. Compromises need to be made.

Friday, 31 December 2021

Annealing Range

Wednesday, 15 September 2021

Digest of Principles for kiln forming

Wednesday, 21 April 2021

Soaks Below the Softening Point

Wednesday, 13 January 2021

Annealing Bullseye and Oceanside Together

|

| Credit: Bullseye FAQ_kilnforming_annealing |

Revised 2.1.25