Friday, 7 February 2025

Frit by thermal shock

Monday, 30 December 2024

Breaks after the Piece is Cool

Thermal Shock

If the break occurs after the piece is cool, it is not thermal shock.

Annealing

Another possible cause of delayed breakage is inadequate annealing. Most guidelines on annealing assume a flat uniform thickness. The popularity of tack fused elements, means these are inadequate guides on the annealing soak and annealing cool. Tack fused items generally need double the temperature equalisation soak and half the annealing cool rate. This post gives information on how the annealing needs modification on tack fused items.

Compatibility

- Compatibility is much more than the rate of expansion of glass at any given temperature.

- It involves the balance of the forces caused by viscosity and expansion rates around the annealing point.

All is not lost. It does not need to be left to chance.

If you are buying by CoE you must test what you buy against what you have.

Do not get sucked into the belief that CoE tells you much of importance about compatibility.

Saturday, 28 December 2024

Breaks in Slumping - diagnosis

- sharp edges indicate breaks on the cool down;

- rounded edges indicate breaks on the heat up.

|

| www.warm-glass.co.uk |

Wednesday, 5 June 2024

Diagnosing Slump fractures

Once you have an initial idea of the source of the problem, think about it. Test it against the evidence. Is there enough evidence to make a call? Make sure you have considered alternative explanations. It is just too easy to make a snap decision about causes in low temperature processes. The source of breaks in slumping are most often complex and stem from interrelated factors.

I give you an example of the difficulties of diagnosing a

slumping break.

On a Facebook group a person showed the break of a single

layer on a cyclone mould. Others

commented the same had happened to them.

Picture credit: Esther Mulvihill Pickens

Possible causes suggested on Facebook included:

- Thermal shock on the way up

- Thermal shock on the way down

- Too large on the mould and broke due to differential contraction

- Too many holds on the way up

- Too hot

- Too thin

- Follow the CPI programme

- Glass extending over the sides

Some of these suggestions were of general applicability,

some in relation to the state of the broken glass.

The suggestions did not include:

- Cause of the rounded dots at the bottom of the mould.

- A cause for the state of the flat piece off the mould (it appears sharp edged. Does it show some forming already?).

- The cause for the location of the fully formed remaining glass.

- The effect of the location of the mould and glass in the kiln.

- The consequences of a short soak at top temperature.

- Is the kiln running hotter than most (1290ºF/698ºC for 10 minutes at top temperature was used)?

Of course, it is difficult to diagnose a problem from just

one picture. It is difficult even with many pictures. And so, without handling

the object, only suggestions can be made.

But….

You must spend enough time examining the piece with whatever

other information is available to make specific suggestions. The first thought may not consider all the

factors. Consider what kinds of causes there

are for breaks during or after slumping.

More close inspection reveals the rounded edges of the

break. That supports the idea that the

temperature was too high. It also supports the diagnosis that the break

occurred on the heat up.

The edges of the piece that has fallen off the mould, and now

rests on the shelf, seem to be square or sharp. This shows the extent of the

difference of temperature between shelf and top of the mould – less than

100mm/4 inches. Also, how small the

differences in temperature are between slump and tack. The extent of difference in fusing does

depend on how high in the kiln the mould is placed. That is demonstrated here by the different elevation

of the two pieces.

The conformation of the glass to the mould is complete. This supports the diagnosis of the break occurring early in the firing, and certainly before the slump was complete. These pieces will not fit together. So, even if the edges were sharp the fact they will not fit together shows they conformed independently to the mould surface. Therefore, the break was before forming temperature was reached.

The glass hangs over the mould edges on only three sides and

at an angle. This indicates the cause of

the overhang was the break. Not the

reverse. An overhang at the beginning of the slump is likely to be even.

The piece on the floor of the kiln combined with the

movement of the glass toward the back gives an indication that the origin of

the break is at the front. This relates to

uneven temperatures and to the placement of the mould.

No one mentioned the placement of the mould and glass at the

back of the kiln. This will have an

effect on scheduling. The mould and

glass are very large in relation to the kiln. There is little space between the glass on the

mould and the walls of the kiln. Also, the

mould is placed asymmetrically in the kiln – very close on three sides. This will cause uneven heating in any kiln. To have a successful firing of glass on this

mould in this kiln will require radically different schedules to that for a

centrally placed mould that is moderate for the size of the kiln.

The large size (relative to the kiln) and the asymmetrical

placing are the causes of the break, in my opinion. I admit that it took me several looks to

realise the placement was a key cause of the break.

So, the generalised comments about thermal shock are correct, but not as to the cause of that shock. The kiln will be hotter in the central part

and cooler at the corners. This is true

of all rectangular kilns. The important

thing is to learn how to cope with these temperature differences.

Slow firings to low temperatures with long soaks are the

three important elements. These make up

the heat work of the kiln. Applying this to a schedule means:

- slow ramp up rates – as little as one half the recommended rates for centrally placed moulds that are moderately sized in relation to the kiln.

- Low temperatures present lesser risks to the control of the outcome of the firing. Determining the lower temperature possible requires peeking into the kiln to monitor the progress of the firing.

- Long soaks combined with low temperatures get the kilnforming done with minimal marking of the underside. Low temperature soaks - in excess of 30 minutes - are required to minimise the marking. Observation of the slump will be necessary to determine when it is complete.

My suggestions for the causes of other elements are:

·

Cause of the rounded dots at the bottom of

the mould.

The temperature was too high. 698ºC/1290ºF

is much hotter than needed for a slump. It was hot enough to round edges and small

shards of glass. Which shows excessive

heat was received by the glass.

·

A cause for the state of the flat piece off

the mould (it appears sharp edged. Does it show some forming already?)

The soak of 10 minutes was too

short for the temperature in the kiln to equalise from top to bottom. The glass on the shelf may not have reached

650ºC/1200ºF with such a short soak.

·

The cause for the location of the fully

formed remaining glass.

The glass broke and was forced

apart by the size of the expansion differences within the glass. The movement of a piece at the front of the

mould combined with the rearward and side movement of the glass indicate the

origin of the break was at the front. The

distance apart shows the amount of force, and so the degree of reduction in the

ramp rate required to fire this successfully.

·

The effect of the location of the mould

and glass in the back of the kiln has already been discussed.

·

A high temperature is often

considered necessary to pick up all the detail in moulds, whether slump or

texture moulds. The same effect can be

achieved at lower temperatures with longer soaks. The results of this strategy are fewer mould

marks on the bottom of the work.

·

Is the kiln running hotter than most

(Used 1290F/698C for 10 minutes at top temperature)?

This is one that cannot be

answered other than by experiments carried out by the owner of the kiln. Look at the Bullseye Tech Note #1 Knowing

your Kiln for methods of testing temperatures.

In short:

Diagnosis of slumping breaks is more complex than it

appears at first.

More information is available in the eBook Low Temperature Kilnforming, an Evidence Based Approach to Scheduling.

This is available from Bullseye or Etsy

Wednesday, 14 February 2024

Differential Cooling of Transparent and Opalescent Glass

A statement was made on a Facebook group that transparent glass absorbs more heat than opalescent glass. And it releases more heat during cooling. The poster may have meant that the transparent heats more quickly than the opalescent, and cools more quickly.

Yes, dark transparent

glass absorbs heat quicker than most opalescent (marginally), and it releases the

heat more quickly (again marginally) than opalescent. The colour and degree of

transparency do not absorb any more or less heat, given appropriate rates. They

gain the same heat and temperature, although at slightly different rates due to differences in viscosity.

The rate of

heating and cooling is important in maintaining an equal rate of absorption of

heat. The temperature of both styles can become the same if appropriate lengths of heating,

annealing, and cooling are used. The slightly different rates of heat gain can

give a difference in viscosity and therefore expansion. This slight mismatch during rapid ramp rates, might set up

stresses great enough to break the glass. This can occur on the quick heat up

of glass during the brittle phase (approximately up to 540ºC/1005ºF). In fact,

most heat-up breaks occur below 300ºC/540ºF.

The main impact of

differential heat gain/loss is during cooling. Annealing of sufficient length

eliminates the problem of differential contraction through achieving and

maintaining the Delta T = 5C or less (ΔT≤5C). It is during the cooling that the

rates of heat loss may have an effect. The marginally quicker heat loss of many transparents over most opalescent glass exhibits different viscosities and rates of contraction. The

stresses created are temporary. But they might be great enough to cause breaks

during the cooling. Slow cooling related to the thickness and nature of the glass takes care of the differential contraction

rates by maintaining small temperature differentials.

Significance of Differential Heat

Gain/Loss

Uneven thicknesses

and the tack fusing profile both have much greater effects than the differential

cooling rates of transparent and opalescent glass. It may be that strongly contrasting colours (such as purple and white) are also more important factors in heat gain and loss than transparent and opalescent combinations. Cooling at an appropriate

rate to room temperature for these factors will be sufficient to remove any

risk of differential contraction between transparent and opalescent glasses.

Wednesday, 10 January 2024

Identification of Mechanical and Thermal Stress

The Identification of stress is important in investigating the causes of stress. We have well established clues to help us with our glass selection and alteration of our firing schedules. We can get more information about why the cold glass has broken from the scientific literature. The manufacturers of float glass and the installers of large panes investigate thoroughly the causes of breaks in glass that has been installed.

One article - Breaking It Down, Why Did the Glass Break? by Timothy Bellovary from Vitro Architectural Glass - looks at mechanical and thermal stress and distinguishing between the two. This post is quoted extracts from that article. [Text in square brackets are interpolations of mine]. Note that all the illustrations are from the article and are copyrighted.

Source: https://vcn.vitroglazings.com/technical-forumdiagnosing-glass-breakage

Identifying the break origin can provide hints about the following:

·

Mode of

glass failure—Was it mechanical or thermally induced stress?

·

The

stress or tension level at which the breakage occurred.

·

Other

contributing factors—were there digs (deep, short scratches) resulting from

glass-to-glass or glass-to-metal contact? Did a projectile hit the glass? Is

there edge or surface damage?

To find the origin

of a break, the first step is to assess its direction by inspecting the

fracture lines… in the glass. These rib-shaped marks, distinguished by a

wave-like pattern, begin at the break origin and radiate along break branches,

and almost always project into the concave face of these lines.

Figure 1

Diagram of Fracture Line Direction

It’s often helpful to make a basic diagram (see Figure 1) of the

fracture lines. … The origin of the break can be determined by:

·

Drawing

arrows (indicating fracture line direction) pointing into the concave face of

break wave markings in the glass edge.

·

Tracing

point-to-tail of arrows back to the break origin.

Mechanical Stress

Low-stress tension breaks are experienced most

frequently by residential window and IGU manufacturers. The origin of the break

is typically at damaged areas of the edge or surfaces near the edge, such as

digs, scratches or chips. In many cases, breakage from damaged glass occurs

after the initial edge damage is incurred, such as during IGU fabrication,

sashing operations, transportation, job-site handling or storage, or the

installation process.

In Figure 2, the break origin is not 90 degrees to the edge

of the glass, indicating a tension break caused by bending. Low-stress,

mechanical tension breaks often occur from bending at less than 1,500 psi.

Figure 2

Low-Stress Mechanical Tension Break

High-stress tension breaks share one

characteristic with low-stress tension breaks: The break origin is not 90

degrees to the edge of the glass, suggesting a tension break caused by bending.

However, additional branching of the crack within two inches of the break

origin (see Figure 3) indicates that the stress at breakage was likely higher

than 1,500 psi.

…

Figure 3

High-Stress Mechanical Tension Break

Thermal Stress

Thermal stress

breaks often originate at the edge of the glass and form virtually 90-degree

angles to the edge and surface of the glass.

As with mechanical

stress, there are two types of thermal stress breaks: low stress and high

stress.

Low-Stress Thermal Break

Low-stress

thermal breaks are

often indicated by a single break line starting at the break origin point at or

near the glass edge and propagating two inches or more before branching into

more break lines (see Figure 4). Damaged glass edges are the most frequent

cause of low-stress thermal breakage.

High-stress

thermal breaks appear

as a single break line starting at the break origin point at or near the glass

edge and generally branching into additional breaks within two

inches [50mm] of the origin. This indicates a breakage brought on by conditions

that cause high thermal stress, such as severe outdoor shading on parts of the

glazing; heating registers located between the glass and indoor shading

devices; closed, light-colored drapes located close to the glass; or glazing in

massive concrete, stone or similar framing.

Figure 5

High-Stress Thermal Break

Analysing the Break Origin

A reliable method for estimating the stress level of a

break at failure is a mirror radius measurement. Radius dimensions are

determined by crack propagation velocity characteristics.

A crack propagates itself through glass with increasing

velocity as it moves further from the point of origin. If an object has

sufficient energy to propagate a crack through the thickness of the glass, then

a “spider web” pattern will form. ….

Near the point of origin, a smooth, mirror-like appearance

on the fracture face indicates a low crack velocity. However, as velocity

increases (due to higher tension stress), the fracture face takes on a frosted

look; then, at the highest velocity, it assumes a ragged or hackled appearance.

Mirror radii appear in various forms, depending on the stress level of the

fracture.

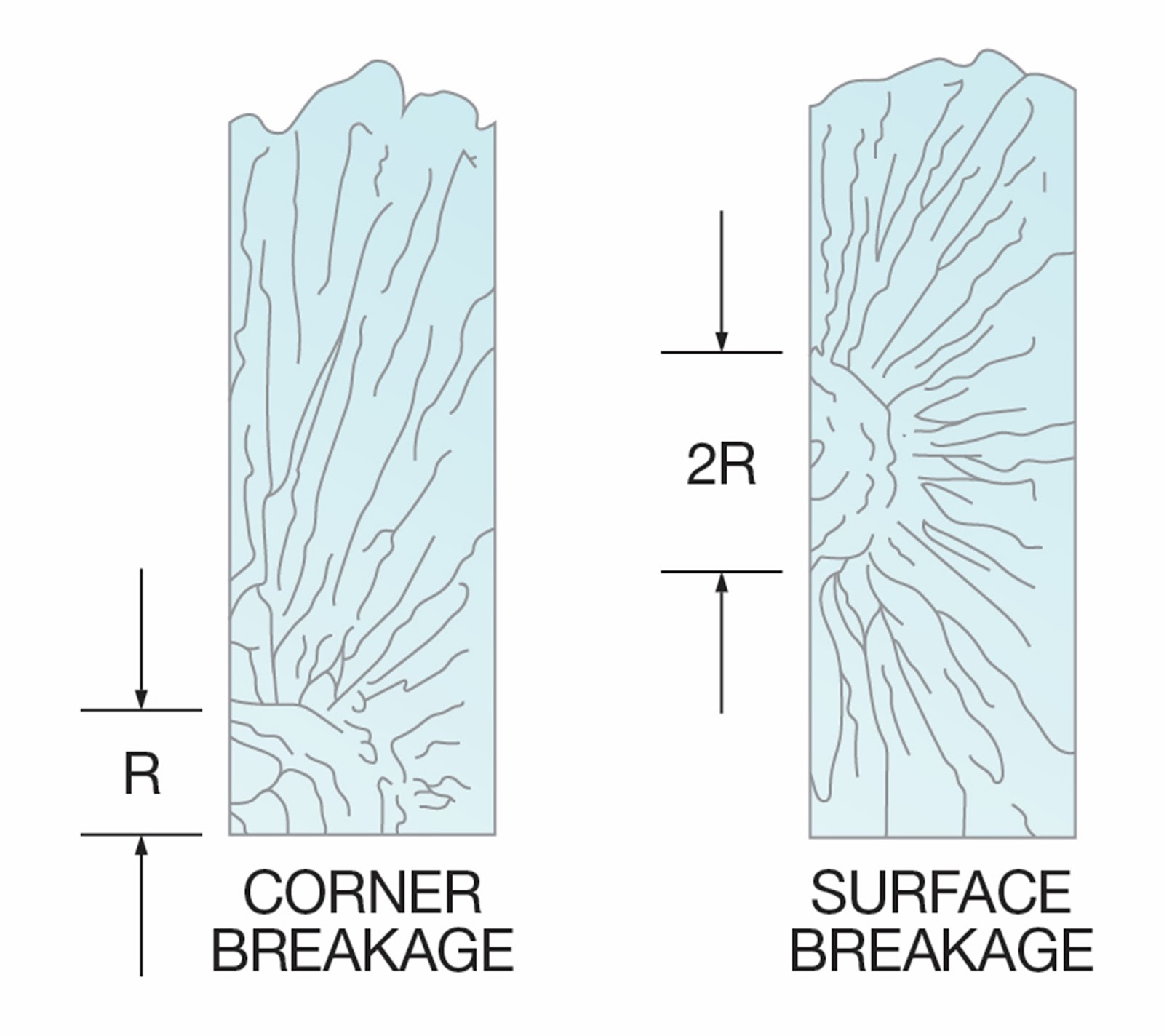

Figure 6 shows break origins resulting from high tensile

stresses, such as bending or thermal stress breaks.

High-Stress Mirror Radii

(R = Mirror radii)

Figure 7 represents the break origins of glass fracturing

at low bending stresses. In this example, a smooth fracture face forms across

the thickness of the substrate. When the breaking stress is low, the mirror

radius is often radial and may extend deeply into the substrate.

Low-Stress Mirror Radii

(R = Mirror radii)

To identify what damaged the

glass in the first place, four factors are examined during this analysis:

·

Impact

·

Inclusions

· Thermal variance

· Pressure differentials

Impact

Identifying the nature of the breakage pattern can

determine whether a foreign object hit the glass and whether the impact was

perpendicular or parallel.

Depending on the severity of the impact, the immediate area

surrounding the break origin might be cracked, crushed or missing.

Figure 9

High-Stress Mechanical Breakage

[This pattern of break is often exhibited when the

separator fails or is insufficient to keep the glass from sticking to the

ceramic support shelf.] …

Inclusions

Any undesirable material embedded in glass is considered an

inclusion. ... [In general, kilnformers place inclusions within the glass and

know the risks of breaks].

Thermal Variance

[This article relates to float glass installations, but the

principle remains.] If the temperature difference across a [piece] of glass is

great enough, the accompanying stresses can reach levels that cause breakage. …

The combination of contact, surface damage and localized temperature gradients

can greatly increase the likelihood of breakage.

Pressure Differentials

[This section applies mainly to Insulated Glazing Units. It

points out that differences in altitude between the manufacturing and

installation sites – in combination with temperature – can cause breaks. It is

not of primary importance to most kilnforming, but something which should be considered

when installing kilnformed glass in an IGU]

Conclusion

[Occasionally] glass breaks for no obvious reason. Whether

it’s a one-off or part of a continuing pattern of incidents, glass breakage is

inconvenient, potentially dangerous and costly. … Conducting “post-mortems” on

glass breaks helps investigators identify the general reasons for each

incident, including the type of failure that caused the break, and the

potential original source of the damage. By using the techniques outlined in

this article, [kilnformers] may be able to accurately identify the likely

origin of such failures and … use that information to prevent future

occurrences.

https://vcn.vitroglazings.com/technical-forumdiagnosing-glass-breakage

[An important element in identifying breaks in kilnforming

that this article demonstrates is the difference in the angle of the break. A

90 degree angle to the surface indicates a thermal cause to the break. The more

branching of the lines of breakage, the greater the stress. The branching

breaks indicate there was significant temperature difference.

The breaks which are less than a right angle to the surface

indicate a mechanical origin of the stress. This is usually the glass breaking

at a weak point when subject to a bending stress.

If the point of origin of the stress can be identified as

demonstrated in the article, it may help in determining causes. One of these

causes might be hot or cold spots in the kiln.]

Wednesday, 21 April 2021

Soaks Below the Softening Point

Saturday, 22 June 2019

Strain Points and Annealing Ranges

“Can you dumb down the concepts of 'annealing point' and 'strain point'? I understand anneal point to be a fixed point (depending on the glass) but the strain point is a range...is this correct? I understand the concept of a hold at the anneal point but I'd like to understand how to bring it down through the strain point.”

I really dislike the idea of dumbing down concepts in kiln forming glass. Glass chemistry is incredibly complicated. Glass physics is still little understood. Glass is a very complicated subject. The marketing of glass for kiln forming has led us all to think it is a simple matter of recipes. Well it's not.

Having got that rant out of my system.... Let’s go ahead.

The annealing point is roughly defined as the temperature at which the glass (if it is the same temperature throughout) will relax most quickly. In the practical kiln forming that we do, it is not possible to ensure that the glass is that temperature throughout. So it is better to think of an annealing soak at the annealing point to allow the glass to become a more even temperature throughout its thickness. As thicker glass means the heat has further to travel from the centre to the surfaces, a longer soak is needed for thicker glass.

The annealing occurs during the slow cool past the lower strain point. The annealing occurs best with a slow, but steady drop in temperature. So annealing is occurring over a range, not at a point. We all rely on a combination of the manufacturers' recommendations, various writings we read, and experience to determine that rate, although Bullseye have published a chart which is most helpful, whichever glass you use.

Strain points.

There is an upper and lower strain point, although this is disputed by some. There are mathematical definitions for these as well as observational definitions. I do not understand the mathematics of either. In lay terms, the lower strain point is that temperature below which no further annealing can take place. It is safe to assume this is 50C below the annealing point (I think it actually is 43C, but I'm not certain of this number).

So it is safest to control the cooling to at least 5C below the lower strain point. Bullseye find that cooling from the annealing soak to 370C is best - this is much more conservative than is theoretically required – 146C below the annealing soak point. This does take care of any problem of thermal shocking of the glass during the cooling.

The upper strain point might be more properly described as a softening point. This also has scientific definitions. The way I think of it is as being the temperature above which no annealing can occur. Another is to think of it as a point beyond which the molecules of the glass are in relatively free motion - which increases with temperature. This again can be considered (on the rise) as 50C above annealing. However on the way down it is safer to consider it to be not more than 30C above annealing. This is because the glass temperature lags behind the air temperature (which is what our controllers measure).

So there is no point in soaking more than 30C above annealing in an attempt to equalise the temperature throughout the glass. However, if you really need to equalise temperature at some point above the annealing point, it might be better to slow the cooling from the working/top temperature and do the final equalisation of temperature at the annealing point.

To answer directly, the strain point by definition of language cannot be a range. There are two points which form the possible annealing range, although the lower one is the critical one. The upper one I described earlier as the softening point. The softening point forms the upper part and the strain point forms the lower part of a range in which the annealing can occur. So the concepts are the opposite of what you propose. They are points which are the boundaries of the annealing range.

To complicate things further, not all glass from one manufacturer has the same annealing point. The published annealing point is a compromise that their experiments and experience have shown to be most suitable. Bullseye glass for example has three annealing points, 532C for opals, 505C for cathedrals and 472C for gold bearing glasses. NOTE: these figures may not be exact; they come from memory rather than documents. Since this list of annealing points was published, Bullseye have conducted further experimentation that shows the best annealing soak occurs at 482C which is below transparent and opalescent, but above gold bearing annealing points.

Schott recommends a range for annealing, not a point, to accommodate these variables. Bullseye, Uroboros, and Spectrum have published annealing points that are practical for people kiln forming in smaller kilns that are less well controlled than the factory lehrs.

If you look at the Bullseye site - education section, you will find a lot of useful information. Especially informative are their tech notes. Spectrum - to a lesser extent than Bullseye - gives helpful information. The information from both sites should be absorbed and the principles applied to other glasses.

Finally, kiln forming is deceptively simple. I have spent 29 years discovering how much more there is to learn. This is one of the reasons that glass is such an exciting medium - people keep discovering new things.

Reviewing the above, I realise that I have not answered your question "... how to bring {the temperature} down through the [lower] strain point". My answer is that you should look at the manufacturer's site for each glass that you use. Look at their rates for annealing for different thicknesses of glass (some also take into account the size). Consider them. Then look at some of the other sites for their published annealing rates for various thicknesses. Comparison of their rates will reveal differences. Think about what they are, how they relate, and whether they reveal that they are using the same principles with slight variations.

Also, if you can, get a copy of Graham Stone's book "Firing schedules for glass, the kiln companion". It provides a handy guide to annealing rates. But DO NOT use it as a book of recipes. Read all the commentary about the schedules, as they (combined with the introductory parts) give principles and tips about how to think about the cooling of the glass. Bob Leatherbarrow has recently published an excellent book on kilnforming schedules, available from his website.

By the way, experience is so often lost, or misremembered, that keeping a log is essential. My first log consisted of loose leaf binder, so I could file all the same kind of firings for various glasses together (this was in the days when there was not much fusing compatible glass, and I couldn't afford Bullseye at UK prices. I was discovering lots about glass firing and using some schedules that I now wonder how I had any success. I did learn a lot from my failures and recorded them too. Now I use a log, usually an out-of-date A4 size diary, sometimes a manuscript book that is big enough to record observations and illustrations. Bullseye have a good record form on their site.

I congratulate you on your desire to understand the processes. Too many only want to put the glass in and turn the kiln on. That is the desire a number of kiln manufacturers pander to when they put pre-programmed schedules on the controllers. So, don't take any of this as criticism of you or your comments. It is meant in a constructive manner - even though I am told frequently that the manner is blunt, even rude.

Best wishes on continued successful kiln forming.

Revised 22/06/19