Tuesday, 14 October 2025

How do I Evaluate Some Suggestions about Annealing?

Wednesday, 3 September 2025

Shotgun Annealing

Shotgun annealing is chosen when the annealing temperature is unknown or uncertain. The name comes from the characteristic spread of the shot pellets to include the target.

To follow this process, pick highest relevant anneal temperature. We know soda lime glass has a range from about 540°C/1004°F to 470°C/878°F. Unless you are firing float glass (which anneals between 540°C/1004°F and 520°C/968°F), you can start the anneal cycle at 520°C/968°F and continue it to 470°C/878°F (a 50°C range). The rate to be used is determined by the amount of time required to anneal the piece according to thickness.

To be safe, a shotgun anneal will need double the time to go through the chosen range that a normal anneal soak requires.

- A 6mm/0.25” full fused piece would normally need an hour soak. So the shotgun anneal rate would be 25C/45F per hour over a 50°C/90°F range.

- A 12mm/0.5” full fused piece would normally need a two hour soak. This implies a rate of one quarter of the range or a cool rate of 12°C/22°F over the range.

- A 6mm/0.25” tack fused piece would need to be fired for twice its thickness, so as for 12mm/0.5”.

Annealing times for different profiles and thicknesses are given in this blog post: and in this ebook.

If the glass is really unknown or older than fusing glass, a wider shotgun anneal range should be used. This gives a temperature range of 540°C/1004°F and goes to 470°C/878°F, or a range of 70°C/126°F. There is still a requirement for the shotgun process to be double the normal anneal soak.

- So for a 6mm/0.25” full fused piece two hours are required to go through the range, or 35°C/63°F per hour.

- A 12mm/0.5” full fused piece and a 6mm/0.25” tack fused piece will need a rate that takes 4 hours to go through the range, or 18°C/32°F per hour.

Once the slow fall of temperature through the range is complete, there should be a one hour soak to ensure the temperature has been equalised throughout the reduction in temperatures. This is applicable to pieces 12mm/0.5” thick. Thicker pieces need a longer soak at this point.

The final part of the anneal is cooling at a rate appropriate for the thickness and profile. E.g.:

- A 6mm/0.25” full fused piece would be cooled at 83°C/150°F to 427°C/800°F, and then at 150°C/270°F to 370°C/700°F or lower.

- A 12mm/0.5” full fused piece needs a two hour soak, so the cooling rates are determined by that, i.e., 55°C/99°F per hour to 427°C/800°F and then at 99°C/178°F per hour to 370°C/700°F or lower.

There is an alternative process which is used to determine the annealing temperature of an unknown glass. Once the anneal temperature is determined for a glass, there is no need for a shotgun anneal process. This is known as the slump point test.

Much more on the principles and practices of annealing can be found in my e-book. Annealing Concepts, Principles and Practice from Bullseye, Etsy and stephen.richard43@gmail.com

Monday, 30 December 2024

Annealing Strategies

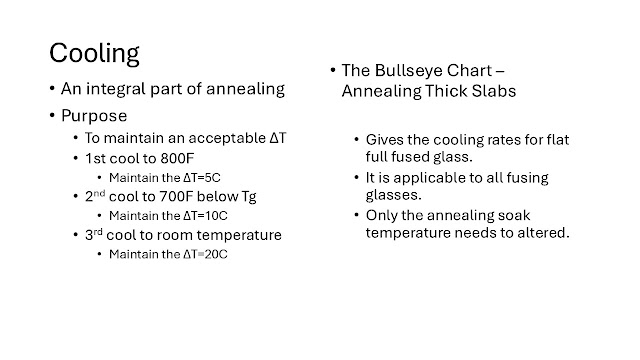

This is a power point presentation I gave a few weeks ago to a group. It may be of interest to others. There is no commentary.

Wednesday, 27 November 2024

Reducing Annealing Time for Float Glass

|

| Credit: Bullseye Glass Co. |

Annealing float glass seems take a long time. The annealing point (Tg) is higher than most fusing glasses, although float glass is part of the family of soda lime glass. This group of glasses should be cooled slowly from annealing temperature to 427ºC/800ºF and below to reduce risks of thermal shock. This makes a greater temperature range over which to anneal float than fusing glasses, consequently it extends the cooling time and increases energy expenses.

It does not have to be this way. Annealing of glass takes place over a range. This range extends below the published annealing point (Tg). This is the temperature at which equalisation can most quickly take place, but it is not as energy efficient as starting in the lower range. Annealing points (Tg) vary between manufacturers, but these are some of them:

Pilkington Optiwhite 559ºC/1039ºF

Pilkington Optifloat 548ºC/1019ºF

USA float (typical) 548ºC/1019ºF

Australian float (average) 550ºC/1022ºF

The annealing range extends to a practical 38ºC/68ºF below the Tg temperature. Annealing at a lower temperature can be as effective at the lower portion of the range as at the Tg. Using a lower annealing soak temperature reduces the temperature range of the first cooling stage by as much as 38ºC/68ºF, and reduces the cooling time without increasing risks of breaking. It also creates a denser glass according to scientific research. Denser glass is arguably a stronger glass.

This means that the annealing of

float glass can take place at the following reduced temperatures:

Pilkington

Optiwhite 521ºC/971ºF

Pilkington

Optifloat 510ºC/900ºF

USA

float (typical) 510ºC/900ºF

Australian

float (average) 512ºC/954ºF

This reduces the first cooling stage for 12mm/0.5” Pilkington Optiwhite from 2 hours 24 minutes to 1 hour 43 minutes. Forty-one minutes may not seem much but in electricity costs is significant. Also using the Bullseye concept of a three stage cooling, further savings can be made. Their research shows the second cooling stage to 371ºC/700ºF can be increased by 1.8 times the first cooling rate, saving further time and energy. The chart which shows these rates is Annealing Thick Slabs - Celsius and - Fahrenheit.

More information on annealing is available in the ebook Annealing: Concepts, Principles and Practice

Annealing float glass at the lower part of the annealing

range reduces the time and cost of firings.

Wednesday, 23 October 2024

Scheduling for Thick Landscapes

Thick slabs often involve numerous firings of increasingly thick work. I am using an existing example, with their permission, of the first stages of a thick landscape. The initial concern was with bubbles in the first layup, then the strategy for firing the thick slab.

Plans

This is the first part of a landscape with depth. It will be fired 5-7 more times. This first piece will be inverted for the

next firing with the clear facing up, to avoid reactions between the colours. It is similar to an open face

casting. There is a Bullseye Tip Sheet on open face casting that will give a lot of information.

Layup

|

| Picture credit: Osnat Menshes |

This work has a base of clear that is mostly overlaid with one layer of 3mm pieces, although in some places another layer, and there are some pre-fired elements as well. It is fired on Thinfire shelf paper.

Bubbles

There is concern about the number and size of the bubbles after the firing, and how to avoid them. Will they grow over the multiple firings?

The many small bubbles are characteristic of kilnformed

glass. The few larger bubbles may result

from the frit that is under the pieces that form the top surface. And there are some overlaps of clear over

colour that may form pockets where air can collect. I advise leaving the scattering of the frit until all the decorative pieces are in place. The bubbles will migrate toward the top during

the multiple firings. They will not grow

in size unless they combine during the upward migration. A later suggestion about

reducing the number of firings will reduce the bubble migration and risk of

increasing in size.

|

| Picture credit: Osnat Menshes |

Schedule

Proposed Schedule (Temperatures in degrees Celsius)

1: 180 – 560, 30’ I would go to 610 for 30'

2: 25 – 680, 120’ I would use only 30'

3: 220 – 810, 15’ I would set the top temperature at 816, 15’.

4: 9999 – 593, 30’ Eliminate this segment.

5: 9999 – 482, 120’ I suggest one hour soak

8: 55 – 370, off 83 – 427, 0’

7: 150 – 371, 0’

8: 330 – to room temperature, off.

Eliminate segment number 4. Any temperature equalisation done at this

temperature, is undone by the AFAP to the annealing. The temperature equalisation occurs at the

annealing temperature. No soak at an intermediate temperature is required. This blog post gives some information about annealing above and below the annealing point (Tg).

Firing Incremental Layers

The plan is for five to seven more firings. Continuing to build up the thickness on

each firing, may have some problems.

- There is increased risk of compatibility problems when firing a piece to full fuse many times.

- There is a risk of more bubbles and of the existing ones becoming larger as they move upwards and combine with other smaller ones.

- With each firing the thickness is increasing and so becoming a longer firing. This is because the heat up, annealing, and cooling each need to be longer. For example - 6mm needs 3hour cooling, 12mm needs 5 hours, 19mm needs 9 hours.

Multiple Slabs

These are the main reasons that I recommend firing a series

of 6mm slabs separately and combining them in one final firing. Firing a series of 6mm slabs and then combining

them in a single long and slow final firing has advantages.

- The individual pieces do not need to go through so many full fuse firings, reducing the risk of compatibility problems.

- The small bubbles in each firing will not have the chance to rise through all the layers to become larger.

- The total time in the kiln for the combined pieces will be less than adding layers to already fired layers.

Examples

It is often difficult to convince people that firing by

adding incrementally to an existing slab, longer firing times are required than

by firing a group of 6mm slabs and a single combined firing of all the slabs. I give an example to illustrate the

differences.

Annealing

Assume there are to be a total of eight firings (existing

6mm slab and 3mm for each of seven more firings). Also assume that each additional firing is of

3mm. This makes a total of 28mm. Compare

annealing and cooling times for each firing:

Firing

thickness anneal and cool (hours minimum)

1 6mm 3

2 9mm 4

3 12mm 5

4 15mm 7

5 18mm 9

6 21mm 11.5

7 25mm 14

8 28mm 17

Total 70.5

hours annealing time (minimum)

To fire up 5 six millimetre slabs takes less time – 3

hours annealing and cooling time for each firing cumulates to 15 hours. Add to that the final firing of 17 hours annealing

time. A total of 32 hours. This is half the time of adding to the

existing slab at each firing.

An additional advantage of firing 6mm slabs and combining them, is that bubbles can be squeezed out more easily in the final thick slab fring because of the combined weight of the slabs. You could make the individual slabs a little thicker, but that would involve damming each slab. Not an impossible task of course. And it would change the calculations, by reducing the number of firings.

Heat Up

Another time saving is to use the second cooling rate from the Bullseye document Annealing Thick Slabs as the first up ramp rate. Take this rate up to a minimum of 540˚C. Although, this is an arbitrary temperature above the strain point to ensure all the glass is above the brittle phase. It is possible to maintain this initial rate to the bubble squeeze. But with the slow rises in temperature required for thicker slabs, it is sensible to increase the rate from 540 to bubble squeeze to reduce the firing time. Once past the bubble squeeze a more rapid rate can be used to the top temperature.

The heat up times could be about half the minimum cooling times.

A worked example (with

certain assumptions) would be:

Firing

thickness time to top temperature total time.

1 6mm 6.3

2 9mm 7.1

3 12mm 8.4

4 15mm 10.7

5 18mm 15.9

6 21mm 19.4

7 25mm 25.1

8 28mm 29.1 ca.122 hours

But firing five times for 6mm equals 31.5 hours plus the final firing up of 29.1 hours equals a total of 60.6 hours. Again about one half the time of progressively building up a base slab to the final thickness.

Savings

This example shows

that approximately 90 hours of firing time can be saved by making a series of

six millimetre slabs and combining them in a final firing. There is the additional advantage of reducing

the occurrence of bubbles between the layers in the final firing because of the weight of the

combined slabs.

Wednesday, 22 May 2024

Slumping and Annealing bottles

"Can a tack fuse schedule for fusing glass can be used to slump bottles?"

It may be that this

person does not have the confidence to write a new schedule. They may wish to use an existing schedule for

another purpose. The short answer is “Although a Bullseye or Oceanside tack

fuse temperature will be high enough to slump bottles, they are not suitable

for annealing”. There are reasons for

this.

The softening point

of float glass, which is similar to bottle glass, is 720ºC/1330ºF. Slumping would normally be done at about 20ºC/36ºF

above this. You also need a slumping hold at this temperature much longer than

a tack fuse schedule would use.

if you use a tack

fuse schedule for a fusing glass, your annealing will be inadequate. Bottle and

float glass tend to have an annealing point of around 540ºC/1005ºF. An

annealing for fusing glass will be between 515ºC/960ºF and 482ºC/900ºF. This is likely to be too low an annealing point

for bottles. Also, the annealing soak is

likely to be too short. Slumped bottles are very thick at the base where it

folds over the cylinder of the bottle.

This requires a longer anneal soak and slower cool than a schedule for a

tack fuse of fusing glass.

Checking for stress

in the completed work is normal. It is essential

for your finished bottle if you use a tack fuse to fire it.

Schedules should be

devised for the glass and layup of each piece. Transferring a schedule for

fusing to bottle glass is unlikely to be successful.

Wednesday, 13 March 2024

Heat Up vs Annealing

Annealing, in comparison to firing to

top temperature, is both more complex and more vital to getting sound, lasting

projects completed. Skimping on

annealing is an unsound practice leading to a lot of post-firing difficulties.

Annealing is more than a temperature

and a time. It is also the cooling to

avoid inducing temporary stress. That stress during cooling can be large enough to break the glass. This temporary stress is due to expansion

differentials within the glass.

People often cite the saving of

electricity as the reason for turning off at 370ºC/700ºF. My response is that if the kiln is cooling off

slower than the rate set, there will be no electricity used. No electricity demands. No controller intervention. No relay operation.

Annealing at the lower end of the range

with a three-stage cooling provides good results. The results of Bullseye research on annealing

are shown in their chart for annealing thick items. It applies to glass 6mm and much larger. It results from a recommendation to anneal at

the lower end of the annealing range to get good anneals. Other industrial research shows annealing in

the lower end gives denser glass, and by implication, more robust glass. Wissmach have accepted the results of Bullseye

research and now recommend 482ºC/900ºF as the annealing temperature for their

W96. The annealing point of course

remains at 516ºC/960ºF.

Bullseye research goes on to show

that a progressive cooling gives the best results. They recommend a three-stage cooling process. The first is for the initial 55ºC/º100F below

the annealing temperature, a second 55ºC/100ºF cooling and a final cooling to

room temperature.

It is a good practice to schedule all

three cooling rates. It may be considered unnecessary because your kiln cools

slower than the chart indicates. Well,

that is fine until you get into tack and contour fusing. Then you will need the three-stage cooling

process as you will be annealing for thicknesses up to 2.5 times actual height.

Of course, you can find out all the

reasons for careful annealing in my book "Annealing; concepts, principles,

practice" Available from Bullseye at

https://classes.bullseyeglass.com/ebooks/ebook-annealing-concepts-principles-practice.html

Or on Etsy in the VerrierStudio shop

https://www.etsy.com/uk/listing/1290856355/annealing-concepts-principles-practice?click_key=d86e32604406a8450fd73c6aabb4af58385cd9bc%3A1290856355&click_sum=9a81876e&ref=shop_home_active_4