Why is a project record sheet useful?

Some kind of record helps to set down the client and maker

agreements, estimate quantities, determine prices, review past practices for

successes and record possible changes for the future.

Even if you do not have clients, comparing

the record sheets over a period can give you information on how quickly you

work, the amount of glass you use in relation to size and complexity,

information for costing, etc. It can give you confidence in stating - and

sticking to - your prices.

These purposes are clearly different from a kiln log or

firing record. This is much more for

assessment of elements for costing and pricing.

You can, of course, include this with your firing log or vice versa.

What should be included?

Desirable elements include the following. You may have others to add according to your

individual practices.

Initial project information

·

Project description - including dated sketch or

photo or reference to the cartoon.

·

Intended location – autonomous, primary glazing,

encapsulated, attached, etc.

·

Dimensions for both two- and three-dimensional

projects.

·

Delivery date. This may be an estimated or firm

date.

·

Price or estimate – indicate which.

Materials and Equipment

·

Glass types and codes that you will (or have)

used, in case additional glass is required.

·

Amount and cost of glass used during completion.

This is not simply the amount used, but also the amount you did, or would require

to, buy to complete the project.

·

Glass separators – kiln wash, fibre paper, etc.,

including their cost.

·

Kiln use. The number and amount for each firing

of the kiln should be added to account for maintenance, supplies, and

depreciation.

·

Mould use.

A notional figure should be added for each use of a mould similar to the

use of the kiln.

·

Miscellaneous materials including their costs.

Time

The time used to complete the project should be noted as you

go along. It can be divided into various

process – such as cutting, firing, cold working, cleaning – or as a simple

cumulative amount of time on the whole project.

Description of project results

A critique of the project including what might be done

differently, the successes, the discoveries, should be written up at the end of

the project.

What does all this record keeping provide me?

Recording this kind of information provides a record of how

various projects went, how you met any difficulties, what the successes

were. This is useful to look back on

when similar projects arise.

This information is invaluable in assessing materials costs,

and time required for various styles and complexity of projects. It enables a quick and assured way of

estimating the costs of a project when a commission is requested. It gives you assurance about your pricing and

valuation of projects you have completed for craft fairs or friends. You don’t

have to be apologetic about the price of items, because you know the costs.

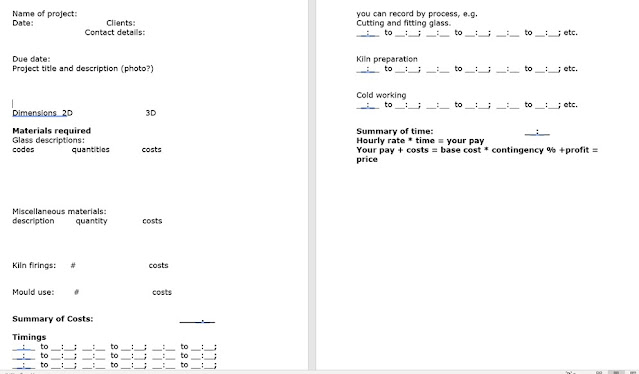

A possible form might look like this:

Project information

Name of project:

Date: Clients:

Contact

details:

Due date:

Project title and description (photo?)

Dimensions 2D 3D

Materials required

Glass descriptions:

codes quantities costs

Miscellaneous materials:

description quantity costs

Kiln firings: # costs

Mould use: # costs

Summary of Costs: ____.__

Processes

The starting and finishing time, including any attention to

equipment should be recorded for each working session on the project. The actual hours and minutes can be added up

later. You can simply record the times

for each project regardless of process, e.g.:

__:__ to __:__; __:__

to __:__; __:__ to __:__;

__:__ to __:__; __:__

to __:__; __:__ to __:__;

__:__ to __:__; __:__

to __:__; __:__ to __:__;

…

Or you can record by process, e.g.

Cutting and fitting glass.

__:__ to __:__; __:__

to __:__; __:__ to __:__; etc.

Kiln preparation

__:__ to __:__; __:__

to __:__; __:__ to __:__; etc.

Cold working

__:__ to __:__; __:__

to __:__; __:__ to __:__; etc.

Summary of time: __:__

Hourly rate * time = your pay

Your pay + costs = base cost * contingency % +profit = price

You will, of course, develop your own form of recording for your

project materials, costs and time used.

But it is important to keep some record of what amount of effort and

cost has gone into each project. With the

passage of time, things seem easier and less costly than they did at the

time. A record of the project reminds

you of the actual costs, difficulties, processes and time.

Maintaining a project record sheet is essential for stained glass artists. It aids in client agreements, cost estimation, pricing, and self-assessment. Including project details, materials, time, and a critique enhances efficiency and pricing accuracy. Regular review offers insights for improvement.

ReplyDeleteglazier