Wednesday, 3 February 2021

Consignment Terminology .

Wednesday, 27 January 2021

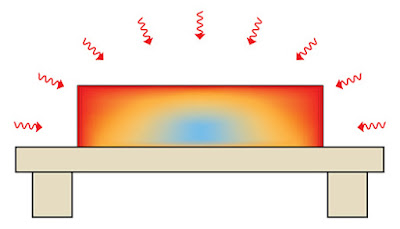

Glue boiling

- Use as little glue as possible.

- Use it at the edges of the pieces.

- Do not place it in the middle of large pieces.

- When you do use glue, advance slowly to at least 300°C allow the glue to evaporate, rather than boil. I’d suggest a rate of 50°C per hour would be slow enough to avoid the boiling of sparingly applied glue.

Quickly fired glue - wet or dry - boils. Sometimes with enough force to move the glass significant distances. Avoid gluing as much as possible and use sparingly when needed.

Wednesday, 20 January 2021

Consignment – meeting the owner/buyer

- Make an appointment, as the retailers’ focus is on selling. Buying is done in down time from the sales.

- Explain how you came to select the shop – this can include recommendations from people already represented by the store.

- Provide a brief description of the kind of work you do. If you sell at other locations – craft shows, online, etc. – include that and be prepared to say how well they sell.

- Be prepared to talk about the inspirations behind your work.

- Prepare yourself with the points you want to make about your work and its relation to the shop’s offerings.

- Remember that you are providing retailers with unique items that fit with their customers interests and needs.

- Be prepared with suggested retail price ranges for each line, remembering the commission the shop takes.

- During the meeting, the retailer will be assessing both your work and the potential working relationship.

- Be prepared for the retailer to ask for time to consider whether to stock your work.

- Take a small but representative sample set of your work in its packaging.

- Back up the samples with good photographs, which are essential, especially if the pieces are too large for practical transport.

- Bring business cards, a resume relevant to the shop, marketing materials, photographs, and samples you are prepared to leave with the shop if asked.

- Dress to make a good impression. You are presenting yourself as well as your work. You don’t need to be super smart. Dress neatly in a way that suits your personality.

- Present your work at its best along with its packaging.

Wednesday, 13 January 2021

Annealing Bullseye and Oceanside Together

|

| Credit: Bullseye FAQ_kilnforming_annealing |

Revised 2.1.25

Wednesday, 6 January 2021

Consignment Venues

- What is its perceived standing? Is it a “go to” shop? Does it get discussed in media? Is it talked about in craft circles? What does its online presence look like?

- Location. Where is it? Is it in a prestigious area? Is it unobtrusive?

- Will there be, or is there already, a good footfall? Who are its customers? Who does the shop target as their clientele?

- What is the fit between the shop and your pieces? Will your pieces fit in with the existing items? Will they stand out well, or seem odd?

- Will the shop advise on the prices they expect to get? Can the shop get you higher prices?

- Does the shop have promotional events that you could participate in?

- Low cost shipping. If your work is large or difficult to post, you can hand deliver.

- Local helps to start small and get experience for larger volumes, more stores.

- Local builds an audience for your work near your studio.

- Getting featured in local press is easier that regional national.

- Local allows for a more intimate relationship to be developed.

- Starting local allows you to learn how to build up the volume of your work.

- What is its perceived standing? How do they perceive themselves?

- What is their media presence? What is the customer perception?

- Location in shopping terms.

- What is the customer base and how does your work fit with that group of prospective purchasers?

- How will your works fit with the shop and its presentation?

- What advice is available on the prices they can get for your items?

- What promotional activities are presented?

- What are the consignment commission rates?

Tuesday, 5 January 2021

Expansion at Edges of Tack Fused Stacks

The most expansion for any thickness and at any tack profile is when the stack is placed at the edge. The further away from the edge, the less the expansion. There is no noticeable expansion of size when the tack stacks are placed 20mm from the edge. In most cases there is only a little expansion at 10mm from the edge. Although not tested, it seems that 15mm is a safe distance from the edge to avoid changing the edge.

The amount of glass in the stack being tacked to the base has an effect on the amount of expansion. This is to be expected based on the concepts behind volume control. Two tack layers can vary from two to three times that for a single tack layer depending on the profile of the tack.

The tack profile has an effect on the amount of expansion. At contour there is a greater expansion than at rounded or sharp tack fuse. This is to be expected, as there is less heat work at sharper tack profiles than at contour.

The thickness of the base has an influence on the amount of expansion too. Thicker stacks promote greater deformation of the edge at all tack levels. Thicker stacks need to be placed further from the edge to avoid changing the perimeter. Thicker stacks create greater change in the edge on single layers than double layers.

|

| Setup for 2 layer base and 1 and 2 layer stacks at various distances from the edge. |

Contour fuse test, 6mm base

1 layer placed at edge, at 10mm from edge, at 20mm from edge, and at 30mm from edge. 2 layer stacks placed in the same way.

|

| Fired results, outlined for clarity |

1 layer placed 10mm from edge – expansion of 0mm

1 layer placed 20mm from edge – expansion of 0mm

1 layer placed 30mm from edge – expansion of 0mm

2 layers placed 10mm from edge – expansion of 2mm

2 layers placed 20mm from edge – expansion of 0mm

2 layers placed 30mm from edge – expansion of 0mm

1 layer placed at edge, at 10mm from edge, and at 20mm from edge.

2 layer stacks placed in the same way.

1 layer 10mm from edge – expansion of 0mm

1 layer 20mm from edge – expansion of 0mm

2 layers placed 10mm from edge – expansion of 1mm

2 layers placed 20mm from edge – expansion of 0mm

|

| Fired result of 6mm base with 1 and 2 tack layers, rounded tack. |

1 layer placed at edge, 1 at 10mm from edge, 1 at 20mm from edge, 1 at 30mm from edge. 2 layer stacks placed as above.

1 layer 10mm from edge – expansion of 1mm

1 layer 20mm from edge – expansion of 0mm

1 layer 30mm from edge – expansion of 0mm

2 layers 10mm from edge – expansion of 1mm

2 layers 20mm from edge – expansion of 0mm

2 layers 30mm from edge – expansion of 0mm

|

| Fired result of 3mm base with 1 and 2 tack layers. |

1 layer placed at edge, 1 at 10mm from edge, 1 at 20mm from edge, 1 at 30mm from edge. 2 layer stacks placed as above.

1 layer 10mm from edge – expansion of 0mm

1 layer 20mm from edge – expansion of 0mm

1 layer 30mm from edge – expansion of 0mm

2 layers 10mm from edge – expansion of 0mm

2 layers 20mm from edge – expansion of 0mm

2 layers 30mm from edge – expansion of 0mm

Wednesday, 30 December 2020

Float annealing

Wednesday, 23 December 2020

Consignment

Why sell on consignment?

|

| Biscuit Factory, Newcastle |

- Finding suitable shops and stores and assessing them.

- Preparation for meeting the owner.

- Knowing your terms

- Placing and promotion of your work.

- Maintaining the relationship.

- Wholesaling

Wednesday, 16 December 2020

Mould repairs with ciment fondue

|

| This mould had glass stuck to it and was damaged in removing the glass. |

Wednesday, 9 December 2020

Clumping Kiln Wash

Applying new kiln wash repeatedly over old leads to uneven application and clumping of the new.