I had a piece crack due to an annealing oops. I put powder on it and put it back in at a higher temp with a much longer anneal time. It looks great on the front, but I can still see where the crack was on the back. Is it supposed to be like that? I didn't think to put powder on that side.

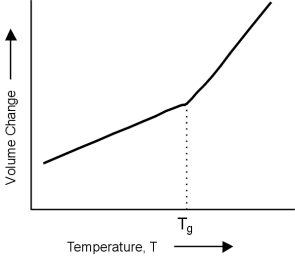

If you think about

why you get crisp lines at the bottom of a strip construction and a more fluid

appearance on the top, you will be near the answer of why a repair looks ok on

top but shows the crack on the bottom. The

temperature on the bottom of the glass is less than on the top at the working

temperature. And less again than the air temperature which we measure. This

means that the bottom part of the glass has less chance to fully recombine.

This, combined with the resistance to movement of the glass along the shelf,

results in evidence of the crack being maintained.

|

| Credit: Clearwater Glass Studio |

There are some things that can

be done to minimise the evidence of the crack. Make sure you know why

your piece cracked before you try to mend it. An annealing crack will need

different treatment than a thermal shock crack or a compatibility crack. Simply

refiring the piece may only make the problem worse.

One approach is to place a sheet

underneath. Make sure the broken glass is well cleaned and firmly pushed

together. Dams may be useful to keep the glass compressed together. Glass

expands both horizontally and vertically during the fusing process. Confining the

glass will transfer most of the expansion in a vertical direction. This

additional (small) vertical movement may help in forming the glass seamlessly. The

broken glass now being supported by an unbroken sheet will enable the movement

required to “heal” the crack.

If you do not want to change the surface, you can fire upside down. To do this you need to have a loose bed of powdered kiln wash, or whiting (a form of chalk) that is thick enough to press the textured side fully into the separator. Make sure the glass is pressed together without any separator getting into the crack. One way to ensure the crack does not open is to use a small amount of cyanoacrylate (super) glue which will burn away during the firing. Put a sheet of clear glass over and fire. Thoroughly clean the face after this repair firing. The ultimate top needs to be fire polished to remove the evidence of the crack, and if it has picked up any marks from the powder.

You could, of course, fire

upside down in this way but without the additional sheet, to avoid making the piece any thicker. This

may or may not work well. If the base layer is one layer thick, it may pull in

at the sides and pull apart at the crack where it is one layer thick. It is also possible that bubbles will develop in the thin parts

of tack glass because of the uneven thicknesses.

A final note. Placing powder on the back will not improve

things. The powder will not fully incorporate with the glass and so leave a

rough surface without concealing the crack.