Diamond quarry glazing appears to be simple. But because if its simplicity it must be both accurate and aesthetically pleasing. Diamond quarried windows look best if the individual pieces are taller than they are wide. The window also looks better if the lines forming the diamonds end in the corners of the window as it gives a pleasing wholeness.

|

| Simple sketches to show the relative clutter of a 6x6 and a 4x4 pattern |

You can try making a sketch and trying various options of numbers and angles. By this simple exercise, you can determine the amount of clutter (how many lines vs. how much glass shows) produced by various combinations. It is important that the proportions of your sketch should be the same as the that of the window for which you are designing. This sketching process lets you try out various numbers of quarries along the bottom and sides quickly as the lines do not have to be accurate. Once you have decided on a size that looks good on the sketch you can count up the number of divisions on the horizontal and vertical lines. This can then be translated into approximate sizes on the full sized cartoon.

Begin with the cut line cartoon. This seems obvious, but until you have measured the window and given the glazing and border leads allowance you are unable to design a damond quarry glazed window that will have its lines meeting the corners in the finished window.

|

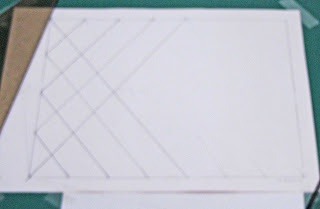

| Drawing the diagonals |

Begin the designing process by drawing two diagonal lines from the corners of the panel to ensure the lines will finish in the corners. This will also determine the centre of the panel and show you the slope of the diagonals. If you have not already determined the size of the diamond quarries, you can try out different sizes of diamonds by drawing parallel lines to the diagonals.

|

| Centre point determined, trial sizes of quarry, and the sides divided |

When you have a size you

like, you can determine the number of diamonds horizontally and

vertically across the panel. You need to measure the width and

height – point to point – of the test diamond and divide the

lengths of sides to determine the number of quarries up and across

the window.

In this example of a small window (380 mm x 280 mm), the quarry is about 50mm wide and 65 mm high. The exact sizes are not too important. Divide the length of the base and side lines to determine the number of divisions. In this example it is five on the base and six on the side. To get the exact dimensions for the quarries, you can

use the no-calculation method of dividing a line. [link]

The divisions are extended to the opposite vertical or horizontal line to provide points from which to draw the diagonals.

|

| Lef to right diagonal lines drawn |

In this example feint lines were drawn up and down across the panel. This provides a check that the diagonals remain accurate.

|

| Remaining diagonals drawn and confirmed by horizontal and vertical check lines |

Sometimes, however, the corner to corner diagonals are too steep or too shallow to make

pleasing diamonds. Diamond quarries generally have slopes that fall

in the range of 50 – 60 degrees (45 degrees gives square quarries

and anything over 60 degrees gives such a narrow quarry as to be

unplesant). In these cases you need to determine the approximate

angle for the diamond shape before proceeding from the centre point.

|

| Centre found and test diagonal drawn |

In this landscape format example the diamond is horizontal, but otherwise a suitable size, so the dimensions were taken of it to determine the number of quarries on each side. In this case it was seven along the bottom and four along the side.

Normally a 55 degree angle is a suitable middle range slope for diamonds, so you can start

with that to determine what number of pieces vertically and

horizontally are appropriate.

After marking off the equal number of

spaces, you can determine which points will give you appropriately

angled diagonals.

|

| Number of quarries determined and first diagonal drawn |

It is important to count the same number of marks along on the base line as there are marks on the side. You will see in the above picture - if you look closely - the effects of narrowing diamonds if you do not.

|

| The second set of diagonals being added |

After setting the diagonals on the first side and part of the base, continue with the parallel lines to the end.

|

| Completed set of diagonals for a landscape window |

This photo shows the completion of the diagonals. It also shows the need for concentration. I was interrupted and when I came back I drew a line from centre top to the next to last mark on the cartoon. However, as you can see from the erasing, it should have been the corner mark that I drew to. I point this out to emphasise how important it is to concentrate while doing this apparently simple task of joining the marks.