A question about re-fusing:

I have just

taken a large piece, with uneven layers out of the kiln, it went in … and fired

for double thickness. A small piece has flipped and is showing the white side. …

If I cover this with a thin layer of coloured powder frit, does the piece need

the long anneal process when I fire it again, please. I will be taking it up to

the lowest tack fuse temperature possible [my emphasis], so the rest doesn’t change

too much.

When considering the re-firing of a fused piece, even with minimal changes, the schedule needs re-evaluation of both ramp rates and annealing. In this case, the major change is using a sinter firing – “the lowest tack fuse temperature possible”.

Ramp Up Rates

Previously the piece was in several layers.

- The piece is now a thicker single piece and needs more careful ramp rates.

- It is also of uneven thicknesses.

- And you intend to fire to a sharp tack or sinter.

These things make a requirement for more cautious firing. You

cannot fire as quickly from cold as forthe original unfired piece.

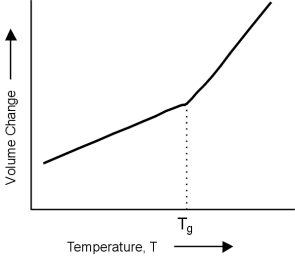

Previously, the sheets could be heated as though separate. They were not hot

enough to stick together until beyond the strain point. They now could

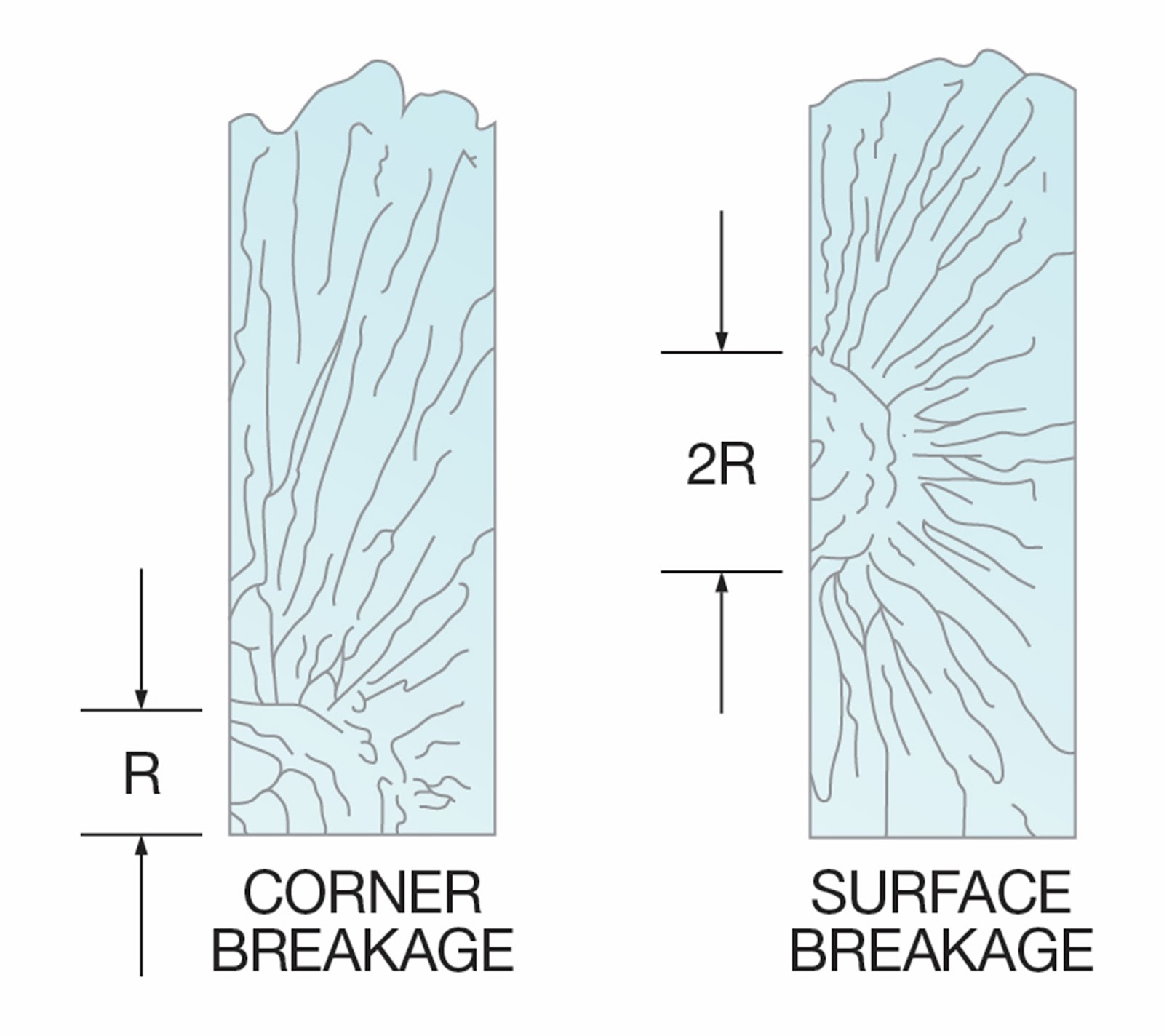

experience the differential expansion from rapid heating, which can cause breaks.

The previously fired piece will need a slower initial ramp rate this time. This is because you are firing for a sharp tack. This is also known as fusing to stick, or sintering. It is not because of a second firing. It is because of the differences in the glass for this firing. You are firing a single thicker piece of uneven layers to a sharp tack.

Looking at Stone* and the Bullseye chart for Annealing Thick Slabs indicates that in general, the first ramp rate should be halved for each doubling of calculated thickness. This is for full fused items. However, this is going to be a more difficult fusing profile - sintering. The calculation for sintering is as for 2.5 times the thickest part of the piece. This factor of 2.5 was determined by a series of experiments that are detailed in the eBook Low Temperature Kilnforming.

You started with firing two layers of 3mm/0.125” at possibly 330°C/595°F. You are now firing the fused 6mm/0.252 piece to a sharp tack. This means you should be looking at firing for 2.5 times or 15mm/0.625”. This implies 240°C/435°F as the maximum first ramp rate. A more cautious approach is to fire to 300ºC/540ºF at a rate of 72ºC/130ºF, as most heat-up breaks occur below that temperature. You should maintain that rate to 540°C/1005°F afterwards.

Annealing

The annealing time and cool rate will be affected in the same way as the change to a sharp tack firing. Without that fuse profile change, and no change in the profile or thickness of the piece, it could have been annealed as previously. However, changing to a sharp tack means a longer anneal soak is required. This sharp tack annealing is for 2.5 times the thickness or 150 minutes.

Cooling

The cooling rates for this piece are not the same as for the

first firing. A sharp tack firing will require cooling rates of:

- 40ºC/73ºF to 482°C/900°F.

- 72ºC/130ºF f427ºC/800ºF.

- 240ºC/435ºF to room temperature

This applies regardless of the fusing glass you are using, as it is the viscosity which is the important factor in cooling. Viscosity is primarily related to temperature.

Refiring with Significant Additions.

Ramp rate

If there are additions to the thickness, a slower first ramp rate will necessary. If an additional 3mm layer is placed on top of a 6mm base for a rounded tack, you will need to schedule as for 19mm/0.75” (twice the thickest part). This will be 150°C/270°F for the first ramp rate. For a sharp tack, it will be as for 22.5mm/0.825”. The maximum rate will be reduced to 120ºC/216F for the first ramp. This shows the additional caution required for sharper fusing profiles.

Annealing

The annealing will need to be longer than the first firing.

The thickness has changed with the additions of pieces for a rounded tack

firing. Instead of annealing for 6mm/0.25” you will be annealing as for 19mm/0.75”.

This requires a hold of three hours at the annealing temperature and cooling

over three stages:

- The first cool rate is 25°C/45°F per hour to 482°C/900°F.

- The second rate is 45°C/81°F per hour to 427ºC/800ºF.

- The last rate is at 90C°C/162°F per hour to room temperature.

If there are additions, plus firing to the lowest possible

tack temperature – as in the example - the firing must be as for 2.5 times the

actual thickness. Annealing as for 25mm/1” gives rates of:

- The first cool rate is 15°C/27°F per hour to 482°C/900°F.

- The second rate is 27°C/49°F per hour to 427ºC/800ºF.

- The last rate is at 90C°C/162°F per hour to room temperature.

These examples show how dramatically later additions in thickness can add to the length of the firing to re-fire a well-annealed piece without breaking it on the heat-up. It also shows that changing the profile to a sharper tack affects the annealing and cooling times and rates.

*Graham Stone. Firing Schedules for Glass; the Kiln

Companion. 2000, Melbourne. ISBN 0-646-397733-8

As a side note Stone’s book has become a collectable.