The Identification of stress is important in investigating the

causes of stress. We have well established clues to help us with our glass

selection and alteration of our firing schedules. We can get more information about

why the cold glass has broken from the scientific literature. The manufacturers

of float glass and the installers of large panes investigate thoroughly the

causes of breaks in glass that has been installed.

One article - Breaking It

Down, Why Did the Glass Break? by Timothy Bellovary from Vitro Architectural

Glass - looks at mechanical and thermal stress and distinguishing between the

two.

This post is quoted extracts from

that article. [Text in square brackets are interpolations of mine]. Note

that all the illustrations are from the article and are copyrighted.

Source: https://vcn.vitroglazings.com/technical-forumdiagnosing-glass-breakage

Identifying the

break origin can provide hints about the following:

·

Mode of

glass failure—Was it mechanical or thermally induced stress?

·

The

stress or tension level at which the breakage occurred.

·

Other

contributing factors—were there digs (deep, short scratches) resulting from

glass-to-glass or glass-to-metal contact? Did a projectile hit the glass? Is

there edge or surface damage?

To find the origin

of a break, the first step is to assess its direction by inspecting the

fracture lines… in the glass. These rib-shaped marks, distinguished by a

wave-like pattern, begin at the break origin and radiate along break branches,

and almost always project into the concave face of these lines.

Figure 1

Diagram of Fracture Line Direction

It’s often helpful to make a basic diagram (see Figure 1) of the

fracture lines. … The origin of the break can be determined by:

·

Drawing

arrows (indicating fracture line direction) pointing into the concave face of

break wave markings in the glass edge.

·

Tracing

point-to-tail of arrows back to the break origin.

Mechanical Stress

Low-stress tension breaks are experienced most

frequently by residential window and IGU manufacturers. The origin of the break

is typically at damaged areas of the edge or surfaces near the edge, such as

digs, scratches or chips. In many cases, breakage from damaged glass occurs

after the initial edge damage is incurred, such as during IGU fabrication,

sashing operations, transportation, job-site handling or storage, or the

installation process.

In Figure 2, the break origin is not 90 degrees to the edge

of the glass, indicating a tension break caused by bending. Low-stress,

mechanical tension breaks often occur from bending at less than 1,500 psi.

Figure 2Low-Stress Mechanical Tension Break

High-stress tension breaks share one

characteristic with low-stress tension breaks: The break origin is not 90

degrees to the edge of the glass, suggesting a tension break caused by bending.

However, additional branching of the crack within two inches of the break

origin (see Figure 3) indicates that the stress at breakage was likely higher

than 1,500 psi.

…

Figure 3High-Stress Mechanical Tension Break

Thermal Stress

Thermal stress

breaks often originate at the edge of the glass and form virtually 90-degree

angles to the edge and surface of the glass.

As with mechanical

stress, there are two types of thermal stress breaks: low stress and high

stress.

Low-Stress Thermal Break

Low-stress

thermal breaks are

often indicated by a single break line starting at the break origin point at or

near the glass edge and propagating two inches or more before branching into

more break lines (see Figure 4). Damaged glass edges are the most frequent

cause of low-stress thermal breakage.

High-stress

thermal breaks appear

as a single break line starting at the break origin point at or near the glass

edge and generally branching into additional breaks within two

inches [50mm] of the origin. This indicates a breakage brought on by conditions

that cause high thermal stress, such as severe outdoor shading on parts of the

glazing; heating registers located between the glass and indoor shading

devices; closed, light-colored drapes located close to the glass; or glazing in

massive concrete, stone or similar framing.

Figure 5

High-Stress Thermal Break

Analysing the Break Origin

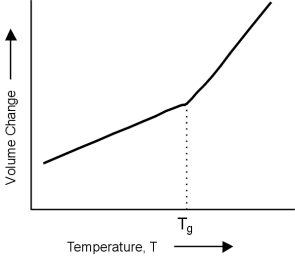

A reliable method for estimating the stress level of a

break at failure is a mirror radius measurement. Radius dimensions are

determined by crack propagation velocity characteristics.

A crack propagates itself through glass with increasing

velocity as it moves further from the point of origin. If an object has

sufficient energy to propagate a crack through the thickness of the glass, then

a “spider web” pattern will form. ….

Near the point of origin, a smooth, mirror-like appearance

on the fracture face indicates a low crack velocity. However, as velocity

increases (due to higher tension stress), the fracture face takes on a frosted

look; then, at the highest velocity, it assumes a ragged or hackled appearance.

Mirror radii appear in various forms, depending on the stress level of the

fracture.

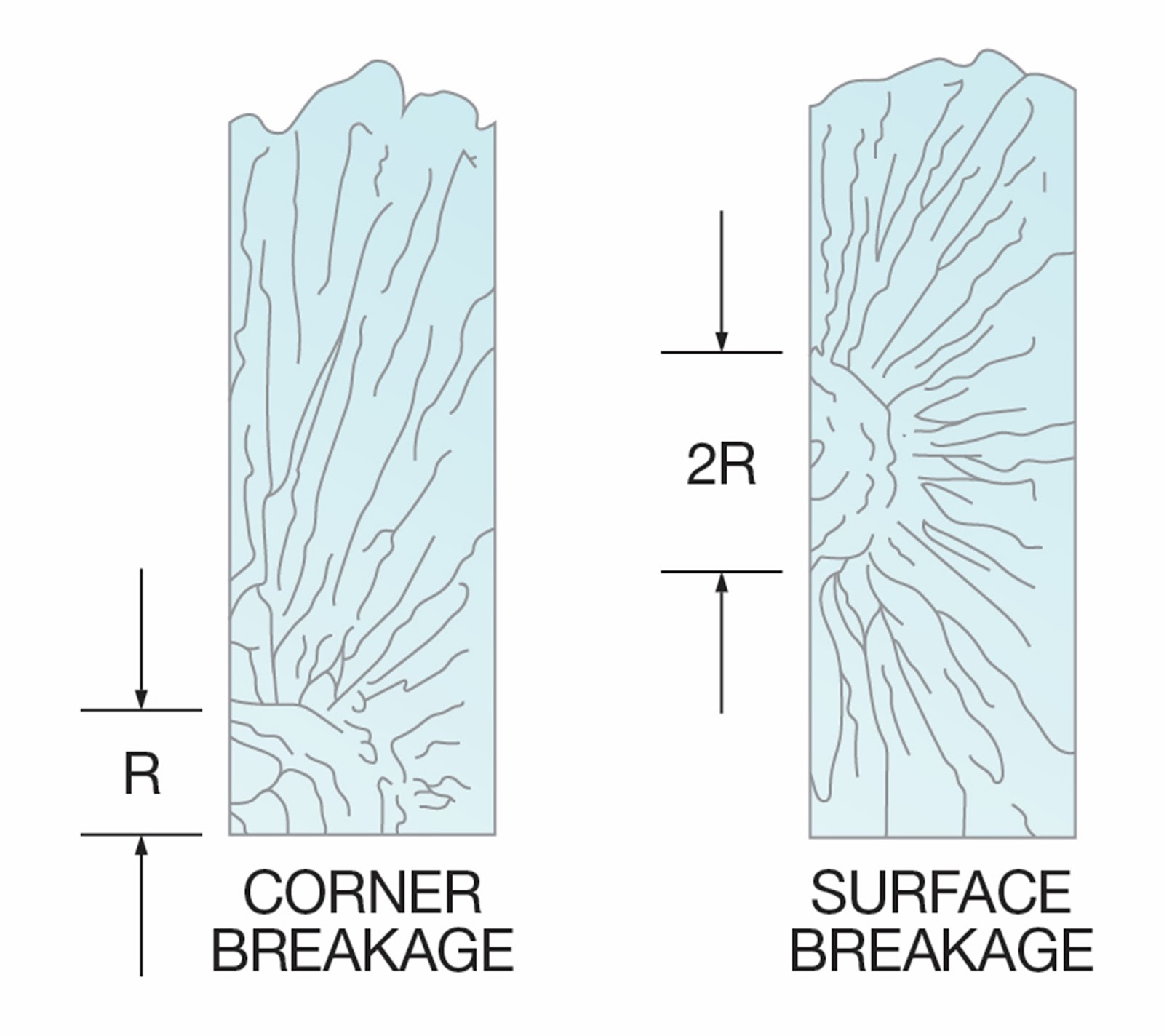

Figure 6 shows break origins resulting from high tensile

stresses, such as bending or thermal stress breaks.

High-Stress Mirror Radii

(R = Mirror radii)

Figure 7 represents the break origins of glass fracturing

at low bending stresses. In this example, a smooth fracture face forms across

the thickness of the substrate. When the breaking stress is low, the mirror

radius is often radial and may extend deeply into the substrate.

Low-Stress Mirror Radii

(R = Mirror radii)

To identify what damaged the

glass in the first place, four factors are examined during this analysis:

·

Impact

·

Inclusions

·

Thermal variance

·

Pressure differentials

Impact

Identifying the nature of the breakage pattern can

determine whether a foreign object hit the glass and whether the impact was

perpendicular or parallel.

Depending on the severity of the impact, the immediate area

surrounding the break origin might be cracked, crushed or missing.

Figure 9

High-Stress Mechanical Breakage

[This pattern of break is often exhibited when the

separator fails or is insufficient to keep the glass from sticking to the

ceramic support shelf.] …

Inclusions

Any undesirable material embedded in glass is considered an

inclusion. ... [In general, kilnformers place inclusions within the glass and

know the risks of breaks].

Thermal Variance

[This article relates to float glass installations, but the

principle remains.] If the temperature difference across a [piece] of glass is

great enough, the accompanying stresses can reach levels that cause breakage. …

The combination of contact, surface damage and localized temperature gradients

can greatly increase the likelihood of breakage.

Pressure Differentials

[This section applies mainly to Insulated Glazing Units. It

points out that differences in altitude between the manufacturing and

installation sites – in combination with temperature – can cause breaks. It is

not of primary importance to most kilnforming, but something which should be considered

when installing kilnformed glass in an IGU]

Conclusion

[Occasionally] glass breaks for no obvious reason. Whether

it’s a one-off or part of a continuing pattern of incidents, glass breakage is

inconvenient, potentially dangerous and costly. … Conducting “post-mortems” on

glass breaks helps investigators identify the general reasons for each

incident, including the type of failure that caused the break, and the

potential original source of the damage. By using the techniques outlined in

this article, [kilnformers] may be able to accurately identify the likely

origin of such failures and … use that information to prevent future

occurrences.

https://vcn.vitroglazings.com/technical-forumdiagnosing-glass-breakage

[An important element in identifying breaks in kilnforming

that this article demonstrates is the difference in the angle of the break. A

90 degree angle to the surface indicates a thermal cause to the break. The more

branching of the lines of breakage, the greater the stress. The branching

breaks indicate there was significant temperature difference.

The breaks which are less than a right angle to the surface

indicate a mechanical origin of the stress. This is usually the glass breaking

at a weak point when subject to a bending stress.

If the point of origin of the stress can be identified as

demonstrated in the article, it may help in determining causes. One of these

causes might be hot or cold spots in the kiln.]