You can use high temperature wire for screen melts. This

is variously described as Kanthal or nichrome wire. It is the same kind of wire used in the

heating elements of your kiln.

|

| wire with bent ends |

To use the wire, you lay or weave the wire and support it on

both ends. Weaving the wire provides

more support, but is not necessary, as the wire is strong enough to support a

lot of glass.

|

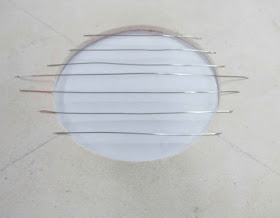

| first line of wires pushed into board |

The wires need support at each end, which can be brick, cut

up shelves, or strips of tile. If you do

this, you can form a dam or vessel in which to put the glass without fear of it

spreading over the edge.

I use fibre board for the support and just bend a right

angle into each end of the wire to push into the board. These can be arranged in any configuration, although for ease of illustration, I have used a rectangular arrangement of wires.

|

| A grid of wires ready for kiln wash |

Put the completed screen over a tray or sheet of plastic to

collect the excess kiln wash. Mix the

kiln wash very thick and pour over the wires. I put the board with wires into

the kiln to heat to about 200°C to help the wash stick. I repeat a few times.

Make sure you coat the area surrounding the screen to avoid

the glass sticking to the supports.

When the kiln wash has dried, knock off the stalactites of

wash on the underside of the wire to prevent any excess kiln wash being

incorporated into the final piece.

Place on kiln washed supports, and put the glass on top of

the screen.

This is a relatively quick and inexpensive means of providing

a custom shaped screen.

One disadvantage

of this over stainless steel rods, is that it is difficult to get enough kiln

wash to stick to the wires to be able to pull them out easily.

No comments:

Post a Comment